生产流程管理系统 Production Process Management System

严控每一道工序,让品质有迹可循

Strict Control of Every Process – Quality with Full Traceability

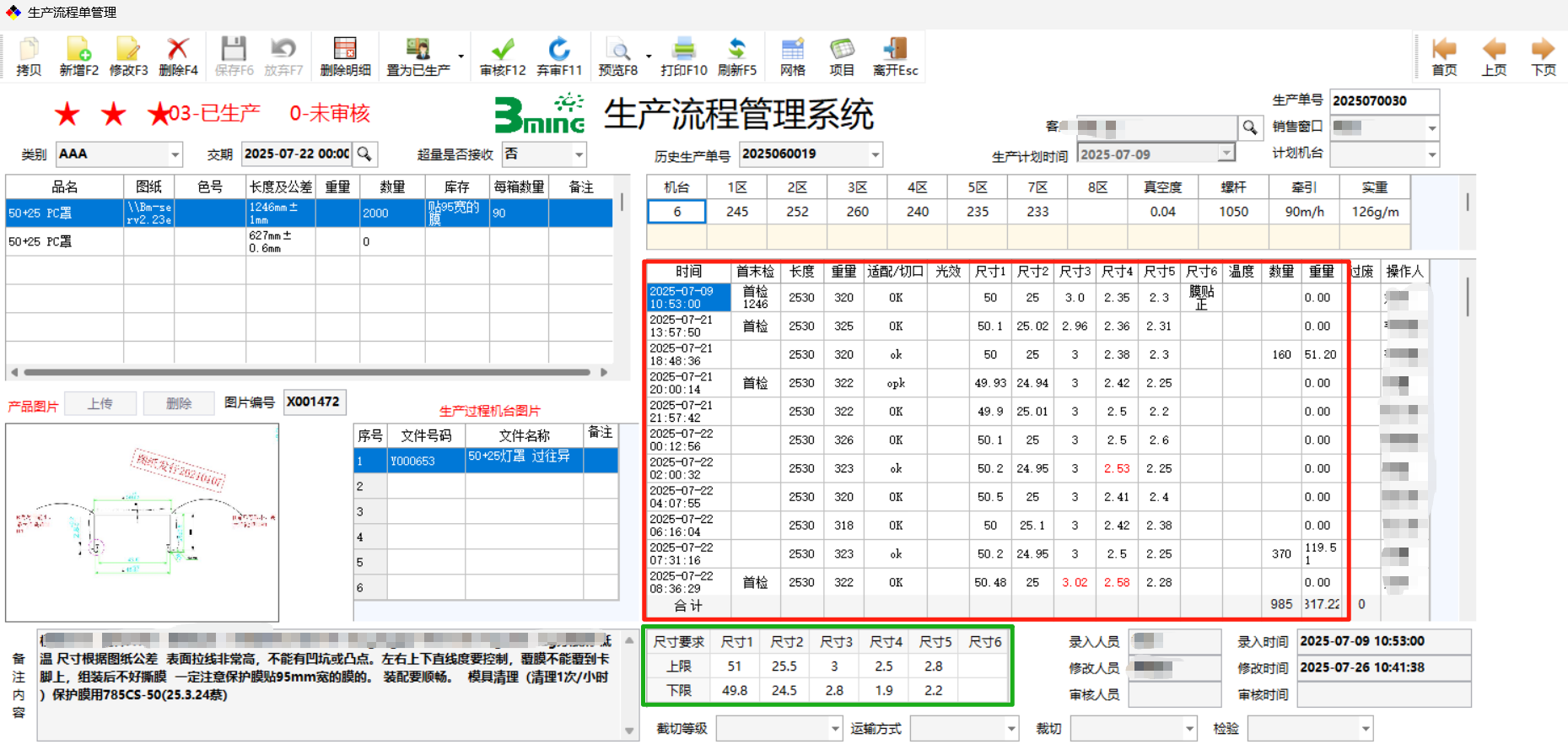

在光学级PMMA/PC线性灯罩的生产中,稳定的工艺控制与可追溯的管理流程是确保产品一致性的关键。宝铭光学建立了标准化、数据化、闭环化的生产流程管理系统,将质量管理贯穿从原料到成品的每一个环节。

In the production of optical-grade PMMA/PC linear light diffusers, stable process control and traceable management are essential for product consistency. Baoming Optical has established a standardized, data-driven, and closed-loop production process management system, integrating quality control from raw materials to finished goods.

核心管理机制

Core Management Mechanisms

🔹 每2小时定时检测与记录

Every 2 Hours, Timed Inspection & Data Logging

- 在挤出、冷却、牵引、收卷等关键工位,每2小时进行一次尺寸、厚度、透光率、表面质量等检测

- 所有数据实时记录于生产报表,形成连续质量趋势图,便于及时发现异常波动

- Inspections are conducted every 2 hours at critical stations (extrusion, cooling, haul-off, winding) for dimensions, thickness, light transmission, and surface quality

- All data is logged in real-time, generating continuous quality trend charts for early detection of anomalies

🔹 全过程质量追溯体系

Full-Process Quality Traceability System

- 每批产品绑定唯一生产批次号,关联原料批次、模具编号、设备编号、操作人员、工艺参数

- 支持从成品反向追溯至生产源头,快速定位问题环节

- Each batch is assigned a unique production lot number, linked to raw material batch, mold ID, equipment ID, operator, and process parameters

- Enables reverse traceability from finished product to source for rapid root-cause analysis

🔹 问题与客诉闭环管理

Closed-Loop Issue & Customer Complaint Management

- 所有生产异常(如尺寸超差、表面缺陷)和客户反馈问题均详细记录、分类归档

- 由质量团队进行根本原因分析(RCA),制定纠正与预防措施(CAPA)

- 更新至内部知识库,并在相关工序中更新作业指导书(SOP),杜绝同类问题再次发生

- All production issues (e.g., dimensional deviation, surface defects) and customer complaints are fully documented and categorized

- Quality team conducts Root Cause Analysis (RCA) and implements Corrective & Preventive Actions (CAPA)

- Updated to internal knowledge base and reflected in revised SOPs to prevent recurrence

🔹 数据驱动持续改进

Data-Driven Continuous Improvement

- 累计数万条检测与问题数据,形成工艺优化数据库

- 定期分析趋势,优化模具设计、设备参数与操作流程,持续提升良品率与客户满意度

- Over tens of thousands of data points form a process optimization database

- Regular trend analysis drives improvements in die design, equipment settings, and operations—continuously enhancing yield and customer satisfaction

为什么这一体系至关重要?

Why Is This System Critical?

✅ 确保产品一致性:避免“这次好,下次差”,每一批都稳定可靠

Ensures Product Consistency: Eliminates batch-to-batch variation—every batch is stable and reliable

✅ 快速响应客户反馈:可精准定位问题批次,提供真实数据报告

Fast Response to Customer Feedback: Enables precise batch tracing and data-backed reports

✅ 预防优于纠正:将每一次问题转化为改进机会,构建长期质量竞争力

Prevention Over Correction: Turns every issue into an improvement opportunity, building long-term quality advantage

✅ 满足高端客户审核要求:完整记录支持ISO、轨道交通等行业认证

Meets High-End Audit Requirements: Comprehensive records support ISO, rail transit, and other industry certifications

在宝铭光学,我们相信:“没有记录,就没有发生。”

Every inspection, every adjustment, every lesson learned is documented—not just for compliance, but for excellence.

在宝铭光学,我们不仅制造灯罩,更用系统守护品质。

At Baoming Optical, we don’t just manufacture diffusers—we protect quality with systems.

浙公网安备33011002015276

浙公网安备33011002015276