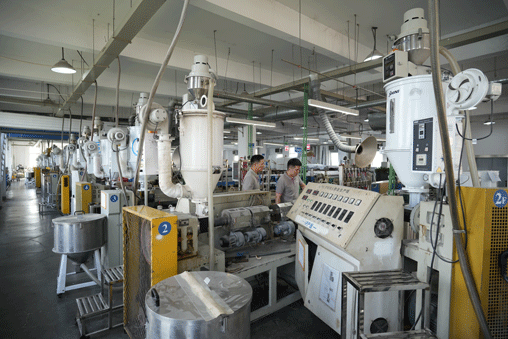

挤出生产线 Extrusion Production Lines

高精度挤出,点亮每一寸光线

Precision Extrusion, Illuminating Every Detail

在宝铭光学,我们深知光学级PMMA/PC材料的性能表现,始于先进的挤出工艺。我们拥有25条专业挤出生产线,全面覆盖从原材料处理、共挤成型、表面压花到在线检测的全流程,专注于线性灯罩、Troffer灯罩、植物照明导光板等高端光学组件的制造。

At Baoming Optical, we understand that the performance of optical-grade PMMA/PC materials begins with advanced extrusion technology. With 25 dedicated extrusion lines, we cover the entire process—from raw material handling and co-extrusion to surface embossing and inline inspection—specializing in high-end optical components such as linear light diffusers, troffer covers, and plant lighting led lens.

我们的挤出生产线具备以下核心优势:

🔹 高精度温控系统:确保材料均匀塑化,减少内应力,提升透光率与耐候性。

🔹 二次元扫描检测:监控型材尺寸公差,精度可达±0.1mm。

🔹 多功能表面处理:支持压花、哑光、亮光、磨砂等工艺,满足多样化光学需求。

🔹 定制化模具开发:可根据客户图纸快速开发非标型材,最快7天出样。

🔹 自动化收卷与包装:提升生产效率,降低人工成本,保障产品洁净度。

无论是商业照明、家居应用,还是高要求的植物生长灯与智能照明系统,我们的挤出生产线都能提供稳定、高效、可追溯的制造支持。

Key Advantages of Our Extrusion Lines:

🔹 High-Precision Temperature Control: Ensures uniform material plasticization, reducing internal stress and enhancing light transmission and weather resistance.

🔹 2D Scanning Inspection: Monitoring of profile dimensions with accuracy up to ±0.1mm.

🔹 Multi-Functional Surface Finishing: Supports embossing, matte, glossy, and frosted treatments for diverse optical needs.

🔹 Custom Mold Development: Rapid prototyping from customer drawings, with samples ready in as fast as 7 days.

🔹 Automated Winding & Packaging: Improves efficiency, reduces labor costs, and ensures product cleanliness.

Whether for commercial lighting, residential use, or high-demand applications like plant growth lights and smart lighting systems, our extrusion lines deliver stable, efficient, and traceable manufacturing support.

浙公网安备33011002015276

浙公网安备33011002015276